The end of the day has finally come and you breathe a sigh of relief and pack up your belongings to head home. As you're picking up your phone, you notice a text from your child asking what you are having for dinner. Panic rushes over you as you realize that you haven't bought anything for dinner and need to make a stop at the grocery store before heading home. As you rush into the store and look around, you notice a section over by the deli with pre-packaged meals. Everything that you need is inside. You can choose to search through the aisles going from one side of the store to other as you decide what you will make, or you can select a pre-packaged meal.

SimplicITy - Is Pre-Packaged Better?

[fa icon="calendar'] Jun 12, 2018 1:10:22 PM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation

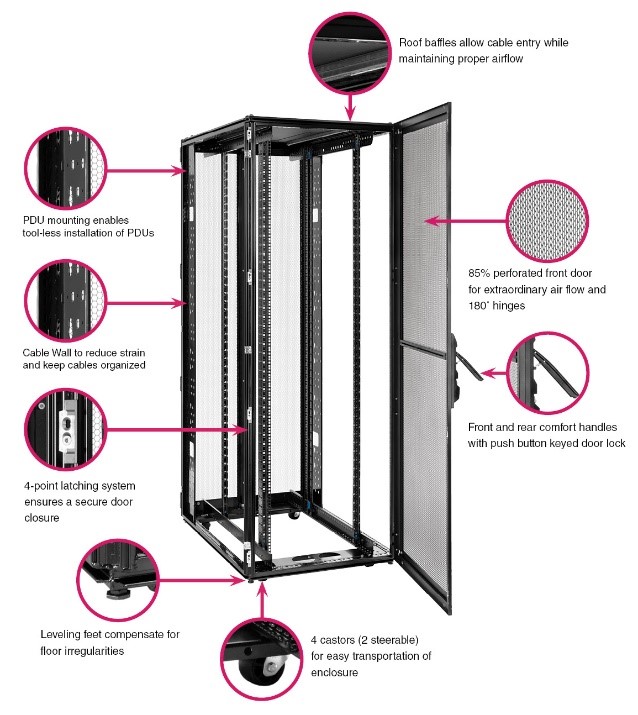

SimplicITy - A Flexible Rack Solution

[fa icon="calendar'] May 21, 2018 10:26:43 AM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation

Edge Computing

[fa icon="calendar'] Apr 4, 2018 11:30:00 AM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation, Rittal Success Stories

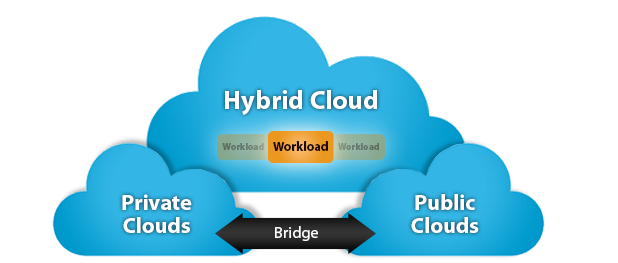

Hybrid Cloud Explained

[fa icon="calendar'] Mar 5, 2018 11:54:41 AM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation

Rittal, Structuring for Success

[fa icon="calendar'] Feb 19, 2018 12:09:12 PM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation

Pneumatechnique: Enclosure Constructor Cuts Costs with Automation Solution from Rittal

[fa icon="calendar'] Jan 18, 2018 9:11:00 AM / by Rittal North America LLC posted in Industrial Automation, Rittal Success Stories, We Are Rittal

British enclosure constructor Pneumatechnique Ltd. was looking for ways to reduce its operating and overhead costs through automation. It found the solution it needed at Rittal: The Perforex machining center reduces the machining time for enclosures, improves the accuracy of recurrent working operations, and allows specialist production staff to be deployed more efficiently.

“Today, we can complete a project in 20 minutes that would previously have taken four hours. At the same time, quality has improved.” Adam Wilson, Production Manager at Pneumatechnique Ltd.

Nestlé, Switzerland: Hygienic Design at the Research Center

[fa icon="calendar'] Jan 16, 2018 11:50:00 AM / by Rittal North America LLC posted in Industrial Automation, Rittal Success Stories

Food hygiene. The Nestlé Product Technology Centre (PTC) in Orbe, Switzerland, is the group-wide research and development center for coffee, chocolate drinks and malt beverages. Nestlé demands state-of-the-art process technology, high availability and hygienic design from its suppliers when purchasing new machines. Enter Rittal.

"We simply want to acquire the best and most modern products the market has to offer." - Phillipe Demarque, Project Manager, Nestlé PTC Orbe

Efficient cleaning

Nestlé has drawn up a comprehensive hygiene specification for all open processes in foodstuffs production. This stipulates how electrical cables are to be fixed in place, regulates the cleanability of

South Coast Controls Improves Conveyor Efficiency and Operations

[fa icon="calendar'] Jan 11, 2018 10:25:00 AM / by Rittal North America LLC posted in Industrial Automation

Attention to the finest details of clients’ needs has elevated South Coast Controls (SCC) as a valued partner to many of its customers. For 30 years, this family company has deliver value-added services for customers purchasing pneumatic equipment and manufacturing control systems. Its expertly designed systems help improve the operational efficiency of its clients, who consistently return for additional projects.

Ford: Rittal Service and Efficiency Check of Cooling Units Reveals Large Savings Potentials

[fa icon="calendar'] Jan 4, 2018 1:18:00 PM / by Rittal North America LLC posted in Industrial Automation

Cologne Ford engine plant shut down a number of times in one year due to defective cooling units. As a result, Ford immediately accepted Rittal’s offer to carry out a manufacturer-independent inventory of all the cooling units and to identify potential energy savings. The analysis by Rittal’s service specialists showed the urgent need to repair and replace 11% of the cooling units installed. In addition, Rittal drew up a comprehensive energy efficiency calculation, which resulted in savings of more than half a million euros within 10 years, with a payback period of just 2.4 years for the investment in the new cooling units.

Water Treatment Plant Challenge: Pumping out a Powerful Solution for Metro Vancouver

[fa icon="calendar'] Nov 29, 2017 10:11:00 AM / by Rittal North America LLC posted in Industrial Automation, Rittal Success Stories

As the second largest secondary treatment facility in Canada, Metro Vancouver Regional District’s Annacis Island Wastewater Treatment Plant (MV AIWWTP) in Delta, B.C., presently serves about 1.3 million people in 14 member municipalities in the Fraser Sewerage Area (FSA).

The pumping facility at the Annacis Island plant is a critical part of the infrastructure, as collection and conveyance systems transport the FSA wastewater to the plant. The three 1,200-horsepower influent pumps and four 684-horsepower trickling filter pumps have been in service for about two decades and were at their end-of-life stage. These large pumps regulate the level of raw sewage in the wet well, conveying it into the treatment plant. Should these fail during high flow situations, there are overflow gates, but these bypass raw wastewater into the Fraser River, which would lead to consequential fines and penalties due to its environmental impact. The trickling filter pumps power the flow of the partially treated waste over trickling filters for secondary treatment, which capture most of the bacteria before the final purification processes.